Many agricultural companies and automotive industries operate in large, open manufacturing spaces. Even modern businesses are eschewing the traditional office space and setting up shop in renovated factories and other open-air structures. While an open floor plan may be practical and commonplace in today’s business world, it creates a problem: a space that is difficult and expensive to heat. Luckily, there is a solution: a waste oil heating system and high-volume, low-speed fans.

HVLS Fans Provide Efficient Air Circulation

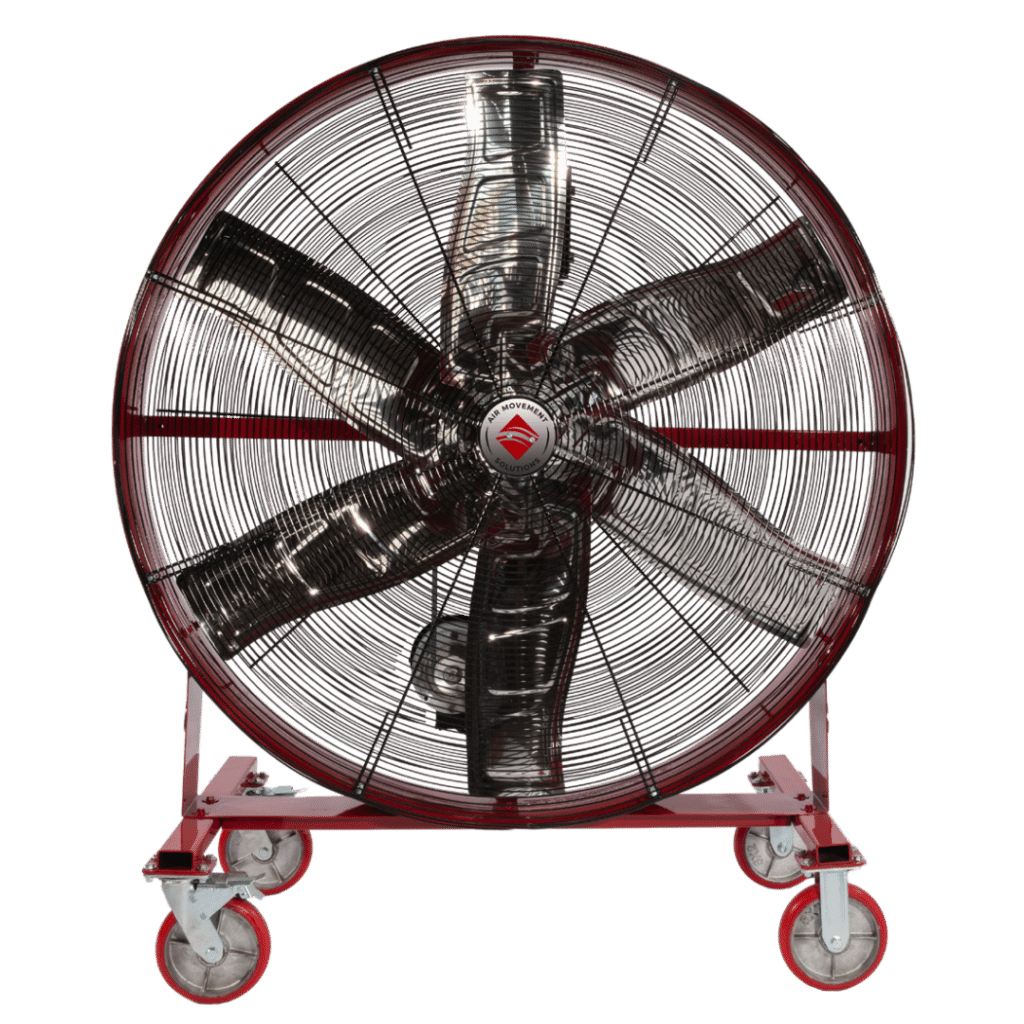

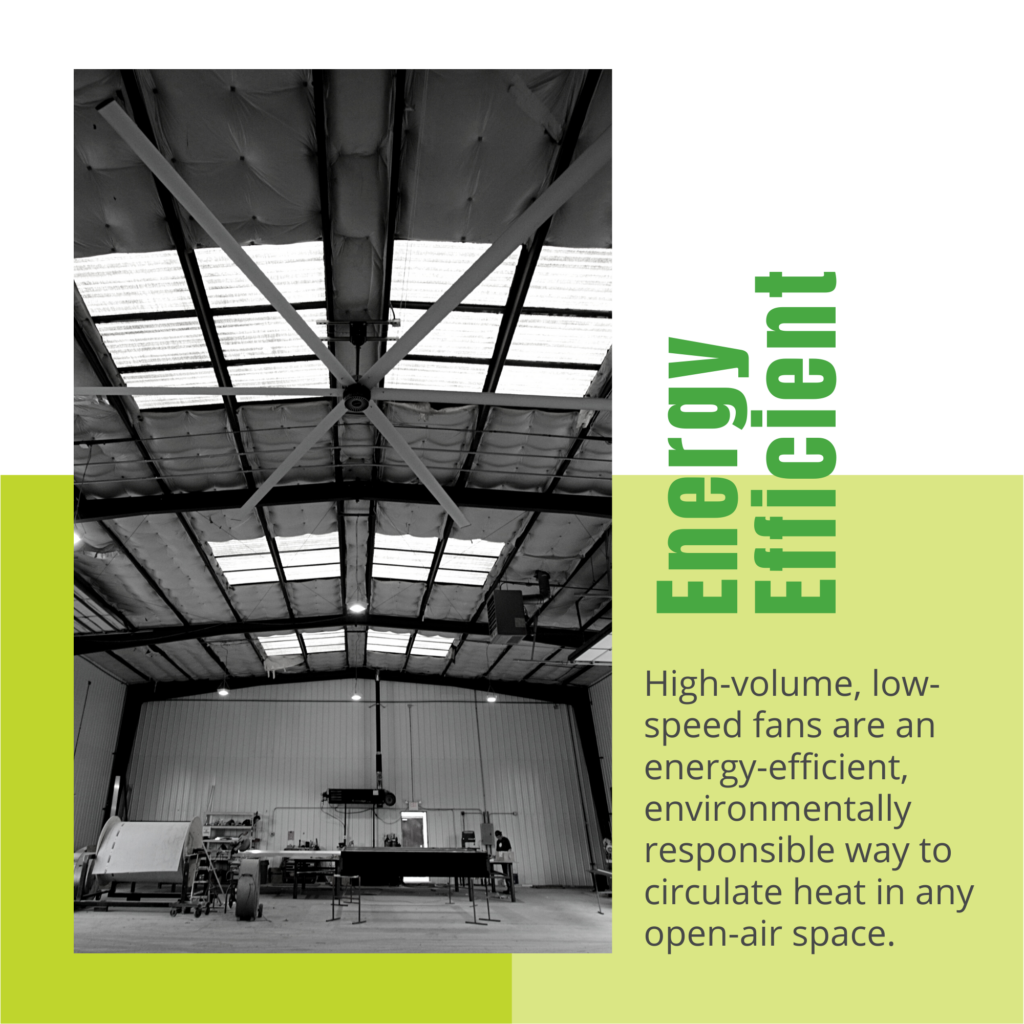

High-volume, low-speed (HVLS) fans may remind you of the ceiling fans in your home at first glance, but they’re much larger. The blades of these fans reach around 20 feet in diameter and spin much slower than typical ceiling fans. This means that HVLS fans can maintain fantastic air circulation capabilities, pushing warm air that accumulates at the ceiling down to the lower levels.

Cost Savings: An Additional Benefit of HVLS Fans

Another practical benefit of an HVLS fan is the energy savings it creates.

MarcoAir HVLS fans have a lightweight and innovative drive system that make them extremely energy-efficient and long-lasting. In winter, HVLS fans can cut heating costs by up to 20% by redistributing the warm air trapped on the ceiling.

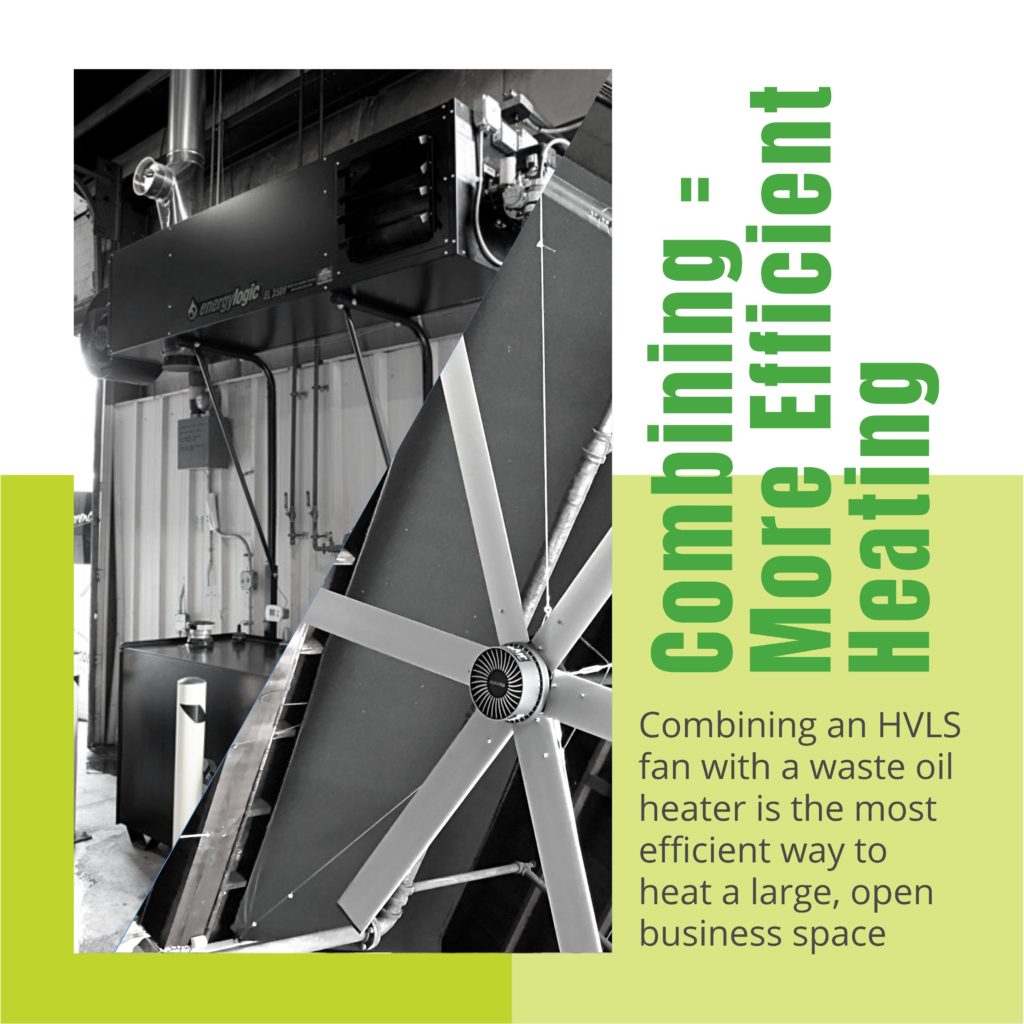

Another way to capitalize on the cost savings potential of an HVLS fan is to use it in conjunction with a waste oil boiler. With this method, you can have ductless heat distribution that uses your facility’s waste oil products as fuel. Essentially, your waste oil burner generates heat from a free fuel, and the HVLS fan circulates the warm air throughout your building. Not only do you save money on utility costs, you save on resource costs since you’re burning waste oils for heating fuel. This energy-efficient, environmentally responsible way of heating is incredibly effective for just about any space.

Hundreds of millions of gallons of waste oils are improperly discarded each year, and these oils can have disastrous effects on the ecosystem, groundwater, and soils in the area. When you repurpose your organization’s waste oils as fuels, you’re reducing the harmful impact that your company might have on the environment, offsetting the heating fuel that would have been used, and helping to create a more sustainable future.

EnergyLogic Waste Oil Boilers

EnergyLogic’s waste oil boilers use your facility’s waste oils as fuel. Using waste oil as fuel eliminates the costs of transport and disposal and reduces your cradle to grave liability. Just about any type of industrial waste oil with weights ranging from 5 to 90 can be burned in a waste oil boiler with no manual adjustments necessary. In turn, your organization saves money on heating costs and oil disposal, and you also gain an effective heating solution for your facility.

EnergyLogic’s waste oil heating systems are easy to clean and maintain with swing-away burners and ash removal ports. You won’t be taking on additional maintenance and manpower costs just to maintain your heating system. You also won’t have to use your own air compressors; EnergyLogic’s waste oil boilers feature built-in air compressors, so your own compressors will be free to use with the tools your employees depend on every day.

EnergyLogic creates a system custom-tailored to your industry, the types of waste oil your operations create, and the spaces that you need to heat.

Applications of a Complete HVLS System

HVLS and waste oil heating complete systems are fantastic when it comes to air circulation and efficient heating. A combination of a waste oil boiler and a HVLS fan means that your facility can have fantastic air circulation and efficient heating without ductwork. This reduces maintenance costs over time, and you’re already lowering your energy costs by recycling waste oil. Add an HVLS big fan, and those savings increase even further.

Many agricultural companies and other organizations with large, open manufacturing spaces have found success using HVLS fans, but these systems can work for any type of company. Even non-industrial, office-based companies may find terrific value in an HVLS system combined with waste oil heating.

If your organization’s facilities don’t already contain an HVLS system, consider investing in one. Get in touch with us here at EnergyLogic to explore how a waste oil heater and HVLS system could be a tremendous value to your company.

Sources:

http://www.inive.org/members_area/medias/pdf/inive/clima2007/a07/a07i1328.pdf

https://www.sce.com/NR/rdonlyres/E714910E-3428-4B62-AC0A-77CB40139776/0/AgDairyFansFactSheet.pdf