Industrial spaces face unique challenges when it comes to climate. In previous blogs we’ve talked about the technology behind industrial fans, and using some of that information, we’ll show you how to use HVLS and industrial fans to address some of the climate issues you may be facing.

If you are still on the fence about getting an industrial fan, consider the recent calculations of the the American Society of Heating, Refrigeration and Air Conditioning Engineers, which showed that customers experienced cost savings of up to 49% after installing HVLS fans! Additionally, a number of independent studies also concludes that a few HVLS fans were as effective as 12 high-speed fans, while providing an 86% reduction in electrical consumption. That’s a lot of savings when you think about it.

Choosing the Right Fan for Your Challenge

There are lots of factors that go into choosing the right industrial fan. Most people will start with the challenges they are facing either cooling or heating a large space. For instance, many areas could be contributing to heating your building, such as:

- Open bays – Large open spaces like this allow the cool air inside to escape when opened and let the hot air from outside to drift in or vice versa in the winter.

- High ceilings – Any space with extra tall ceilings is at risk of a buildup of heat layers.

- Pallet racks – Spaces with large pallet racks or other storage areas act as air flow barriers and block air from circulating.

- Heat pockets – It’s no surprise that large spaces with different areas can have climate zones and temperature pockets.

- Not enough HVAC ducting – Even the best of HVAC systems are not set up to get the cool air to reach all areas of the facility.

- Seasonal temperature swings – Force your air conditioning or heating to work harder than its tonnage and increase humidity and risk of Sweaty Slab Syndrome in your building.

Industrial fans are pivotal in various sectors, including manufacturing, agriculture, mining, and construction. They serve a multitude of purposes, from air circulation and exhaust to cooling and drying. Yet, the diversity in applications means that a one-size-fits-all approach often falls short. Factors such as space limitations, specific airflow requirements, noise restrictions, and environmental conditions demand a more personalized strategy. This is where customization steps in, offering a pathway to efficiency, sustainability, and superior performance.

Tailored HVLS and Industrial Fan Solutions

Customization in industrial fans can take many forms, each addressing different aspects of performance and application. Some key areas where tailored solutions can make a significant impact, include:

- Design and Size Adaptation: Custom designs can accommodate space constraints and integrate seamlessly with existing systems. Tailoring the size and configuration of fans ensures optimal airflow and pressure without sacrificing valuable real estate.

- Material Selection: The choice of materials is crucial, especially in harsh environments. Custom fans can be constructed from specialized materials to withstand high temperatures, corrosive substances, or abrasive conditions, ensuring longevity and reliability.

- Efficiency Optimization: Energy consumption is a critical concern for many industries. By customizing fan blades, motors, and controls, manufacturers can significantly reduce energy usage, contributing to greener operations and cost savings.

- Noise Reduction: In environments where noise is a concern, such as residential areas or workplaces requiring high concentration, customized solutions can include noise-dampening technologies to minimize disruption.

- Advanced Control Systems: Incorporating custom control systems allows for precise management of fan operation, adapting to real-time demands and enhancing overall system efficiency.

Getting HVLS Fan Sizing and Placement Correct

The key to maximizing the benefit of the HVLS fans and addressing the climate issues above is choosing the best product design, the correct size and number of fans, and placing them properly in the space. For more information on product design and the key technology behind the fans, be sure to check out our previous post, The Science Behind HVLS Fans: Understanding the Technology. When it comes to sizing, to get started you should have precise measurements of the facility and blueprints if possible.

- Getting the Right Size and Number of Industrial Fans

When we work with customers to determine the right fans for their space, we need to know key information, including:

- The building’s total volume of air

- Facility shape and set up

- Building materials

- Occupied use

- Desired outcome

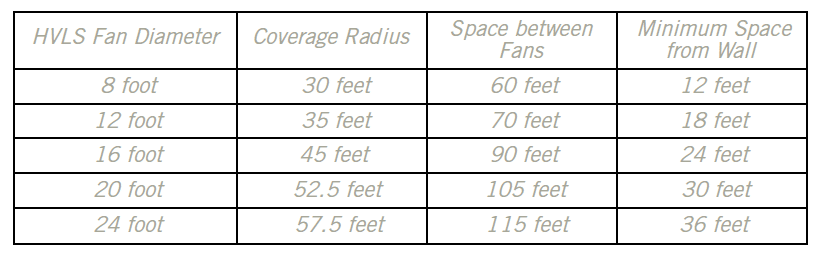

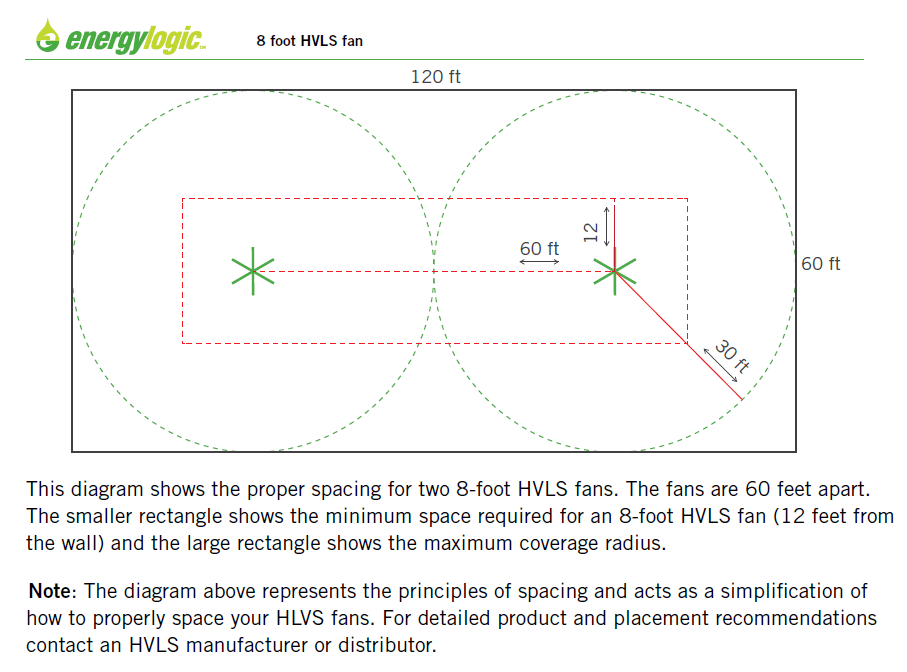

Because choosing the correct fan(s) for an application is complex, it is best to consult the HVLS manufacturer and request an airflow simulation. However, the table below provides a general fans to space comparison for your information.

- Placing Your HVLS Fans Properly

Positioning the fans to overcome ground obstructions is important to ensure full de-stratification of the space. If the obstruction is a single object, like a large piece of stationary equipment, the HVLS fans should be centered above the object whenever possible so that the air column can wash over the obstruction. If there are a series of obstacles, place the fans between the obstructions to allow the full column of air to fall directly to the floor. Because every building design is different, it is best to consult the HVLS manufacturer for installation placement recommendations.

In the realm of industrial machinery, fans stand out not just as essential components for ventilation and cooling, but also as crucial elements in the intricate dance of manufacturing, processing, and environmental control. However, not all facilities are created equal, nor do they face identical challenges. This brings us to the significance of customization in industrial fans – a tailored approach that transforms these machines from mere utilities to bespoke solutions, engineered to meet unique operational needs. As technology advances, the potential for even more sophisticated and responsive customization in industrial fans promises to revolutionize how industries manage air – the very breath of their operations.

Contact EnergyLogic to get your HVLS fans today!