Best in Class Waste Oil Boiler Technology. Deliver the hottest heat for radiant flooring and potable water.

Best in Class Waste Oil Boiler Technology. Deliver the hottest heat for radiant flooring and potable water.

Experience Unmatched Efficiency with a EnergyLogic Waste Oil Boiler

When it comes to waste oil boilers, EnergyLogic is the obvious choice. Why? Because EnergyLogic engineered a boiler from the ground up, specifically for waste-oil and multi-fuel combustion.

Fuel Flow Rate | 1.4 gal/hr (5.3 L/hr) | 2.7 gal/hr (10.2 L/hr) | 3.6 gal/hr (13.6 L/hr) |

BTU's | 200,000 BTU/hour (58.3 kW/hour) | 375,000 BTU/hour (110 kW/hour) | 499,000 BTU/hour (146 kW/hour) |

Water Output Temp | 230°F (110°C) | 230°F (110°C) | 230°F (110°C) |

Capacity | 30 gallons (114 liters) | 43 gallons (162.75 liters) | 52 gallons (200 liters) |

Exhaust Flue Diameter | 8" (20cm) | 8" (20cm) | 10" (25.4cm) |

Boiler Dimensions | 45”H x 32”W x 50”D | 45”H x 28”W x 60”D | 45”H x 32”W x 68”D |

Boiler Weight | 790 lbs | 1042 lbs | 1160 lbs |

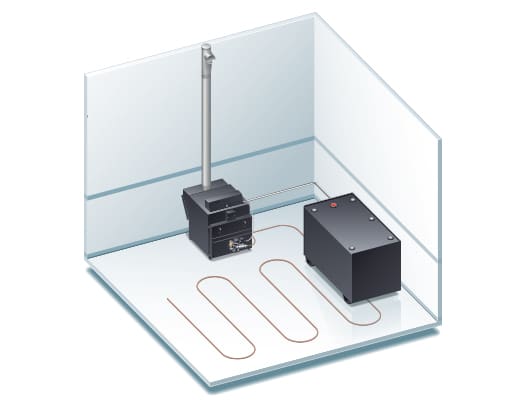

Choose from our six complete systems for a quick and effortless setup. Everything you need, including the boiler, tank, and mixing valve, is included.

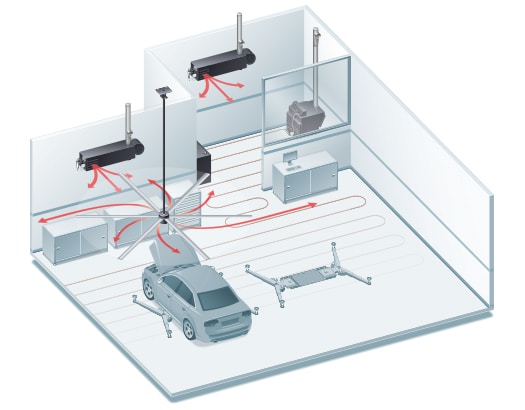

Our custom solutions often combine the unmatched heat of our furnaces with the power of an HVLS fan. Enhancing the effect of heat by redistributing warm air down from the ceiling to the ground where it’s needed most.

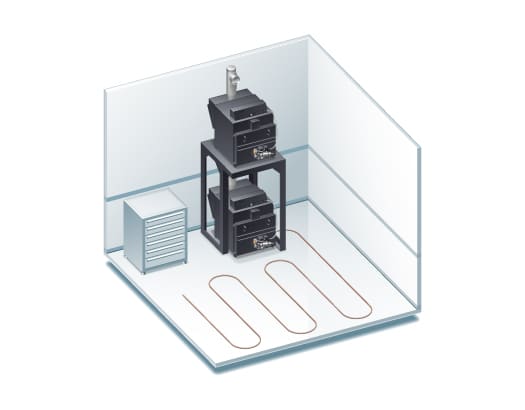

Our boilers not only feature a small footprint, they’re designed to allow for stacking.

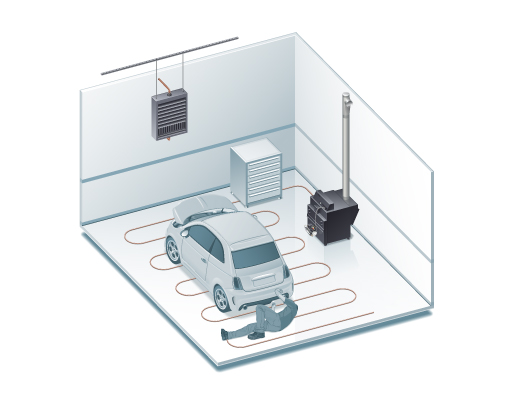

Efficiently warm the entire floor, providing a comforting and cozy environment by delivering heat from the ground up. Effectively eliminate ice on driveways and rooftops while efficiently drying all moist surfaces.

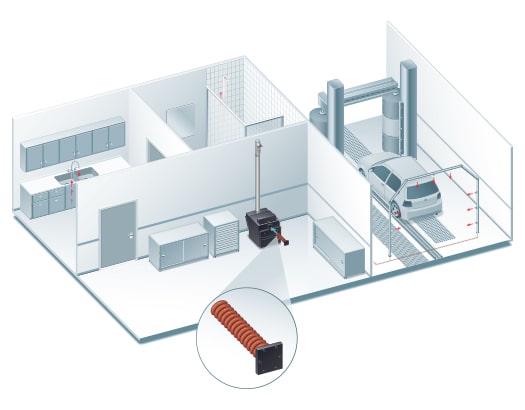

Install our optional domestic hot water coil to use your boiler to heat domestic water.

A waste-oil boiler heating system is made up of two major parts – the waste-oil burning boiler that heats up the water or coolant, and the hydronic piping network that pumps and carries the heated water or coolant around the space. The heat is usually radiated from the pipes in a radiant floor or from convectors and radiators evenly spaced throughout the building.

There are several advantages to this type of radiant heating and the benefits are multiplied when you calculate the cost savings of using waste-oil boiler heating. The water or coolant used in the radiant hydronic system can absorb more heat and holds heat much longer than air. Waste-oil boilers heat buildings and spaces much more evenly and are often used to heat the mass of the building, leading to long slow releases of the stored heat.

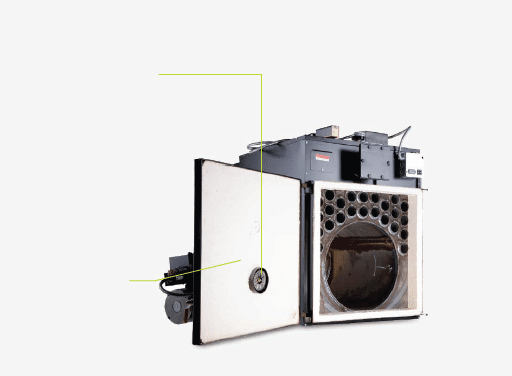

The only boiler vessel built specifically for waste oil from the ground up. Our heavy carbon-steel construction is stronger and more efficient than cast-iron and coil-tube boilers provided by other brands.

Exclusive

Speeds and simplifies straight through cleaning (see below).

Saves space and makes installation simpler

and more flexible with unit stacking and flue options.

Patented

Rapidly heats the widest viscosity range of used oil, synthetic oil,

and other acceptable fuels.

Built-in so you don’t have to connect to and rely on

shop air, providing 24/7 heating availability.

Patented

Reliable, consistent fuel delivery regardless of fuel type

(up to 90W) with no manual adjustments.

Water-cooled heat exchanger prevents hot spots and deterioration.

Tracks runtime.

An open-loop domestic coil can be added to run closed and open loops

simultaneously. Provides hot water for restrooms, carwash, dishwashers,

and more. Unit can operate as a stand-alone system using the hot water coil.

Patented

This patented design creates competing brands. a hotter flame

for complete fuel combustion and the highest heat output. Less

ash is produced resulting in longer maintenance intervals than

competing brands.

Easy access to the firing chamber for cleaning.

Built-in memory & system history provides

diagnostics for efficient operation.

Dynamic temperature reset decreases fuel

consumption by up to 20%.

A back-lit LCD display with a touchpad makes programming temperature

limits, differentials, and other options easy.

Analog pressure gauge continually displays conditions.

Our patented technology ensures complete combustion, generating more heat and leaving fewer residues.

Burn waste oil ranging from 5 weight to 90 weight, including synthetics, without manual adjustments.

Our design maximizes the heat output and ensures efficient distribution, providing optimal warmth.

You don't need to hook up shop air to our furnaces. Now you can use your tools and the furnace at the same time.

With the industry's widest selection of accessories, we can create a tailored solution for your space.

The swing-away burner and ash removal port make our furnaces easy to maintain.

Customize your waste oil boiler to meet your exact needs. EnergyLogic supplies:

Recycled oil contains many impurities, sludge, and even water, and require special holding tanks. EnergyLogic’s storage tanks were developed to handle waste oil, delivering cleaner fuel for superior combustion.

Save significantly on heating bills and collection fees with an EnergyLogic waste oil heater. Try the savings calculator below to see just how much!

Savings Per Year:(values in USD)

10-year Savings(after equipment cost)

An EnergyLogic Waste Oil Heater Pays for Itself in Only:

†Custom: Is your facility not represented here?

Click Get Your Custom Quote to contact EnergyLogic for custom solution.

Information based on U.S. Energy Information Administration. *Based on insulated space with 16ft. ceiling. Results may vary based on geographical & other considerations.

You're making the best decision in waste oil heating.

An EnergyLogic Rep will be in contact within 1-2 business days to help you find the perfect heating solution for your facility.

Download our Buyer's Guide, and be informed with insider industry knowledge.

Copyright © EnergyLogic LLC

We’re so confident in our products, we are the only company to offer a 90-day Moneyback Guarantee on our complete systems, heaters, boilers, and accessories. If you’re unsatisfied with your new EnergyLogic product, we’ll send someone over to you to make it right. After that, if you’re still not happy, you can return the product for a refund of the purchase price, terms and conditions apply*!

EnergyLogic’s warranty covers two years on parts* and ten years on the combustion chamber*. This is one of the longest warranties in the industry. We want you to feel as confident as we do in the quality of our products.

*Money-back Guarantee: the customer must allow EnergyLogic to send a service provider to the customer’s location in order to attempt to resolve any issues impacting performance. In addition, the heating product or system must be installed according to the product instructions in the owner’s manual. If the Waste Oil Heater system or product is still not performing to the customer’s satisfaction, even after a visit from an EnergyLogic service provider, then it can be returned for a refund. Please note that the customer is responsible for any previous installation charges, system or product removal, return packaging and shipping, as well as any missing or damaged parts.

*Warranty on Parts: Receive one year full warranty with purchase. Second year full warranty requires product registration. Other terms and conditions apply.

*Warranty on Combustion Chamber: Receive full warranty for the first 5 years. The last 5 years will be pro-rated.