The Importance of Proper Combustion Draft

Clean, efficient fuel combustion requires the right balance and timing of three key elements: fuel, ignition, and oxygen. To achieve the proper combustion drafts, there must be clean-burning oil, heat to ignite the fuel, and air (oxygen) to support the combustion. When optimized, a waste oil combustion system delivers the desired heat output safely and efficiently without the need for constant user attention.

Today, we look at some of the other benefits of proper combustion draft and how modern waste oil furnaces can help you achieve it.

Increased Personal and Environmental Safety

Proper combustion draft ensures the safety of those in the surrounding environment during the heating process and minimizes the overall environmental impact by ensuring complete combustion.

For example, in an occupied space, responsible combustion requires the carefully controlled management of exhaust gasses and particulates. Too little draft can reduce the combustion air delivery of a burner and cause smoke. However, connecting a furnace’s combustion chamber to a chimney flue system creates a controlled air draft that carries away the exhaust and potentially harmful fumes. At the same time, the chimney draws and delivers enough oxygen to make clean combustion possible.

Over the past decades, the oil and gas industry has used technological advances to make the combustion process in systems even more environmentally friendly. For instance, the waste-oil combustion furnaces at EnergyLogic carefully control the combustion process to offer maximum environmental protection and energy offset. The chimney safely carries away pollutants according to levels required by government environmental policies and regulations, while waste oil is efficiently converted into useful heat.

Additionally, waste-oil products at EnergyLogic use a patented flame retention head design to deliver complete combustion. This means the operator enjoys an ultra-hot flame that incinerates impurities, leading to less ash waste. EnergyLogic understands the importance of keeping environmental safety a top priority and has tailored its fuel-ignition-oxygen recipe to deliver clean heat, releasing exhaust through a precisely calibrated chimney flute.

Optimized Fuel Efficiency

Fuel efficiency is a growing concern for businesses and industries throughout the United States. Modern furnaces must burn fuel with maximum efficiency for best cost-effectiveness and minimal environmental impact. Proper combustion drafts maintain a proportional balance among all three key combustion elements, optimizing fuel usage. Too much draft can evacuate valuable energy before it transfers to the intended application. Conversely, too little draft can mean the furnace does not fully consume the fuel – resulting in dirty operation and energy loss toward the intended application.

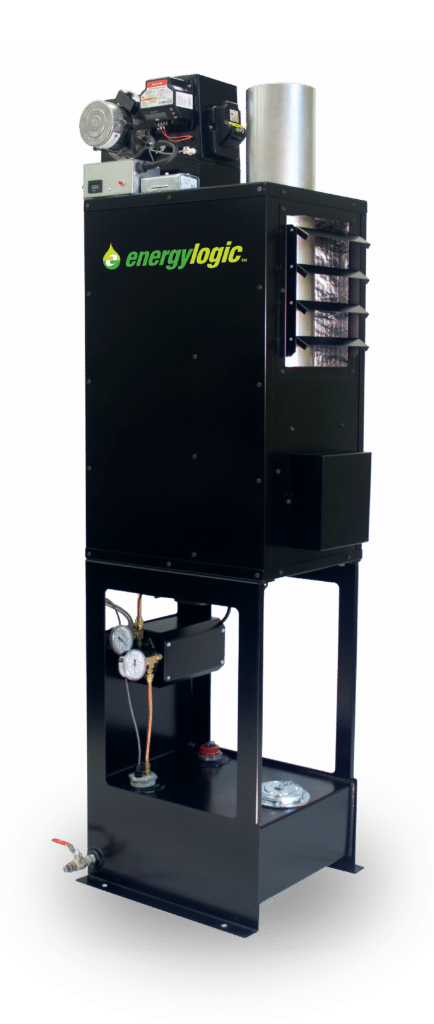

The balance between elements during combustion is crucial to save fuel and result in the least amount of waste. EnergyLogic makes the fuel-ignition/oxygen ratio easy to master. Our waste-oil combustion products use metering pumps, preheaters, onboard air compressors, and draft manometers as standard with our waste-oil combustion products. These components ensure the exact amount of fuel, heat, and air with each application regardless of temperature or viscosity. In turn, the furnace’s performance is optimized whilst the environmental impact is minimized. Since chimney flue configurations vary from one application to another, careful calibration at installation is required to verify proper draft, after which time, no additional adjustments are needed, However, a regular maintenance schedule is recommended.

Proper combustion draft ignites and burns fuel at optimal efficiency around the clock, minimizing operation costs. EnergyLogic heaters run on fuels from 5 to 90 weight, including synthetics. Regardless of fuel type, operators enjoy reliable, consistent fuel delivery without making manual adjustments.

Minimized Maintenance

A properly drafted combustion system can easily lengthen a product’s life and reduce the amount of maintenance necessary. Systems with the proper ratio have longer maintenance intervals due to clean, efficient energy flow throughout the system at all times. This leads to reduced accumulation of ash, superior performance, and fewer contaminants that can wear away at the system.

EnergyLogic takes the hassle out of waste-oil combustion furnaces with quick and simple ash removal. Our heaters have an ash removal port and swing-away burner for easy access to the chamber tube. Our single wide tube accommodates more ash and allows for easier cleaning than most other models, minimizing the need for regular maintenance. When the furnace does require maintenance, the job is fast and easy. Our technical service and how-to videos make maintenance even more of a breeze.

Together, EnergyLogic products and proper combustion draft can make the ideal environmentally friendly, fuel-efficient, and easy to use waste oil heater.